Menu

Close

Close

Don’t hesitate to contact us for more information about company or service

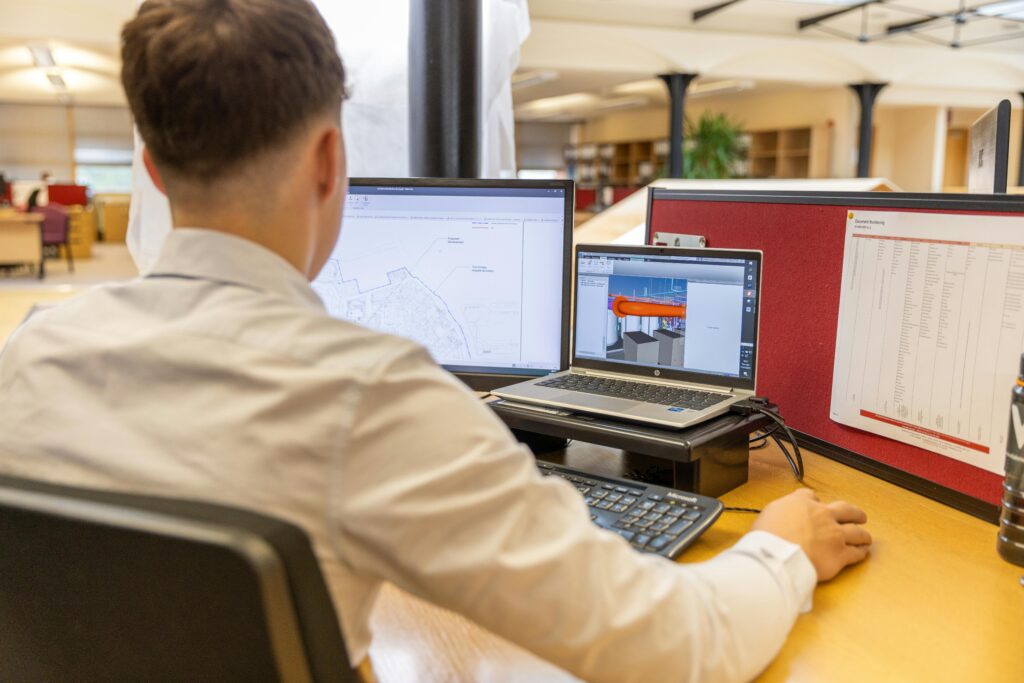

Aries Tech is an Australian engineering company delivering advanced CAD solutions, precision design, and trusted vehicle compliance services. From concept development and reverse engineering to certification for modified and imported vehicles, our team combines technical expertise with a practical, client-first approach.